In a world increasingly focused on environmental protection and sustainable alternatives, pulp molding tableware machines have emerged as a revolutionary solution for producing biodegradable and eco-friendly tableware. These machines convert renewable plant fibers—such as sugarcane bagasse, bamboo, and wood pulp—into disposable plates, bowls, trays, and food containers that can naturally decompose within months.

This guide will walk you through the entire pulp molding tableware production process, the technology behind it, system structures, and the reasons why this green manufacturing trend is shaping the future of global packaging.

What Is Pulp Molding Tableware Technology?

Pulp molding tableware technology is an advanced process that transforms natural plant fibers or waste paper into molded, heat-resistant, and biodegradable tableware through a sequence of pulping, forming, drying, and hot-pressing steps.

Unlike traditional plastic or foam packaging, pulp molded tableware is:

- 100% biodegradable and compostable

- Food-grade safe

- Heat- and water-resistant

- Made from renewable raw materials

This sustainable manufacturing method plays a vital role in replacing single-use plastics banned in many countries worldwide.

Main Components of a Pulp Molding Tableware Production Line

A complete pulp molding production line usually consists of five major systems:

1. Pulping System

The process begins with raw material preparation. Plant fibers or waste paper are mixed with water in a hydraulic pulper to create a uniform slurry.

Key equipment includes:

- Hydraulic pulper

- Pulp refiner

- Pulp screening system

- Water circulation tank

This system determines the fiber quality, which directly affects product strength and surface smoothness.

2. Forming System

In this stage, the pulp is delivered to the forming machine.

Using vacuum suction, the pulp is absorbed onto molds to create wet tableware products in desired shapes such as plates, clamshells, or bowls.

Key equipment includes:

- Forming machine with upper and lower molds

- Vacuum system

- Air compressor

- Pulp supply pump

The forming molds are designed with precision to ensure consistent thickness, texture, and edges.

3. Drying System

The freshly molded products are transferred into a drying system to remove moisture and stabilize their structure.

Drying options include:

- Metal drying line: Fully automatic, energy-efficient, and suitable for large-scale production.

- Multi-layer hot air dryer: Compact design with fast drying speed.

- Natural drying room: Suitable for small-scale production in warm climates.

This stage ensures the molded products achieve the required hardness before hot pressing.

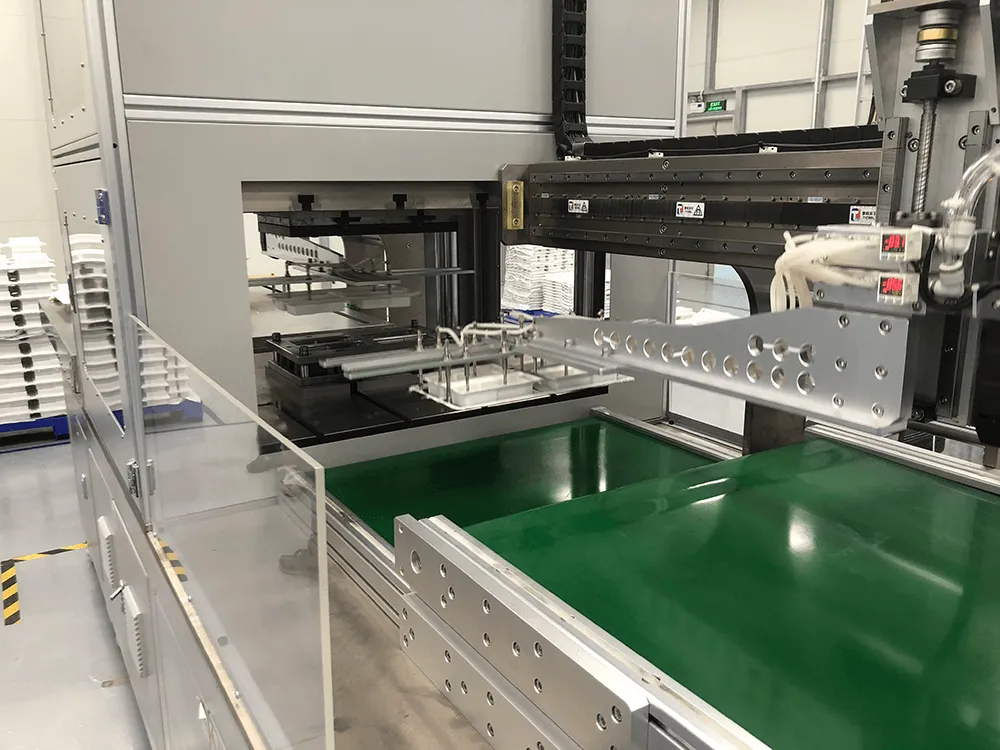

4. Hot Pressing System

Hot pressing refines the product’s surface, improves density, and enhances strength and oil resistance.

Modern machines integrate forming and hot pressing into one system, ensuring precise control over pressure, temperature, and positioning.

This step also defines the final appearance — smooth texture, precise edges, and high-end quality.

5. Trimming, Stacking, and Packaging System

After hot pressing, the finished items are automatically trimmed, counted, and stacked.

Automated systems reduce labor costs and increase efficiency, readying products for direct shipment or packaging.

Types of Pulp Molding Tableware Machines

Depending on the production scale and product type, there are several configurations:

| Type | Description | Applications |

|---|---|---|

| Semi-Automatic Machines | Manual transfer and simple control system | Small-scale workshops, testing, R&D |

| Fully Automatic Machines | Integrated forming, drying, and hot pressing | Large-scale commercial production |

| Integrated Thermoforming Systems | Combines molding and hot pressing into one process | High-end tableware, premium packaging |

Applications of Pulp Molded Tableware

Pulp molding tableware machines are widely used to produce:

- Food service items: Plates, bowls, trays, lunch boxes, cup lids.

- Takeaway packaging: Clamshells, burger boxes, and food containers.

- Retail & catering products: Tableware for supermarkets and restaurants.

- Event supplies: Disposable, biodegradable tableware for festivals and catering.

Future Trends: Smart and Energy-Efficient Production

Modern pulp molding machines are evolving toward:

- Intelligent monitoring systems (real-time temperature & pressure control)

- Energy recycling within drying systems

- High-precision servo control for mold positioning

- Automatic mold switching for diverse product lines

These innovations reduce energy costs, improve product consistency, and make large-scale production more flexible and sustainable.

Conclusion

Pulp molding tableware machines represent the future of sustainable manufacturing.

They combine environmental responsibility, cost efficiency, and modern automation to create biodegradable packaging solutions that meet the demands of a changing world.

Whether you are an investor seeking a profitable green business or a manufacturer looking to upgrade from plastic to pulp, now is the perfect time to embrace pulp molding technology and lead the transformation toward a cleaner, more sustainable future.