Fully Automatic Tableware Machine

Breakthrough technological innovation with low energy consumption, high efficiency, and increased yield as its core advantages.

Daily Capacity: ≥1000 KG (Depend on Product)

Main Features

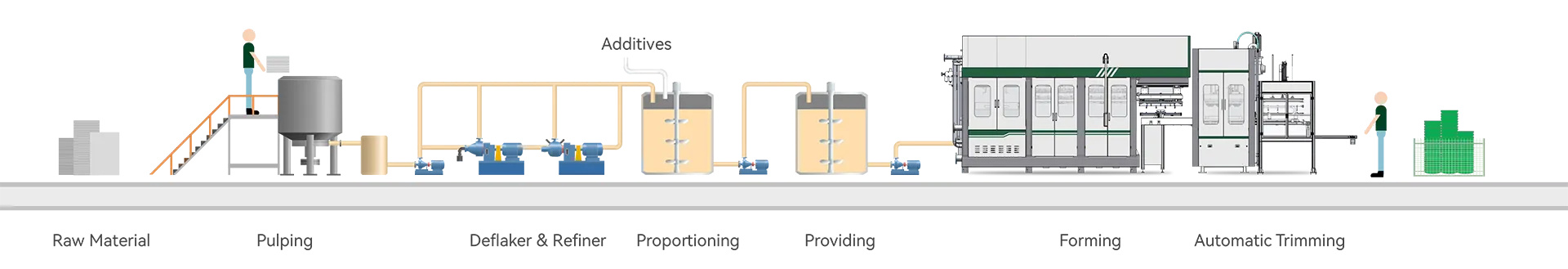

New tech created for the new market has sold over 100 units since its launch. It utilizes renewable plant fiber resources such as bagasse, wheat straw, reed, moso bamboo, and other eco-friendly materials for pulp tableware production. The products have multiple applications, including disposable lunch boxes, dinner plates, bowls, cups, hamburger boxes, and premium egg cartons.

The equipment adopts a linear structure, effectively minimizing space requirements. Advanced pre-dehydration technology significantly improves energy efficiency. With ultra-low moisture content in wet embryos, it reduces the risk of clogging, thereby extending the intervals between mold cleaning and maintenance. Additionally, the system is capable of producing high-profile products with excellent sealing performance and minimal draft angles.

Technical Parameters

| Model | ZC2Q—110110 | |

|---|---|---|

| Product Application | Disposable Tableware, Paper Cups, Premium Egg Carton | |

| Daily Capacity | 1000 KG (±10%) | |

| Platen Size | 1100 × 1100 mm | |

| Heating Energy | Electricity / Thermal Oil (Customizable Upon Request)) | |

| Forming Method | Reciprocating | |

| Hotpress Method / Pressure | Servo Hydraulic / Max 60 Tons Pressure | |

| Trimming Method / Pressure | Servo Five-Point Linkage / Max 80 Tons Pressure | |

| Safety Protection | Self-locking & Auto-stop Design | |

| Max Product Height / Thickness | 80 mm / 1.2 mm | |

Great Feature

- The equipment adopts a linear structure, reducing space requirements and optimizing layout efficiency.

- Advanced pre-dehydration technology improves energy efficiency while minimizing operational costs.

- It produces high-profile products with excellent sealing, small draft angles, and ultra-low moisture wet embryos that reduce clogging and extend mold maintenance cycles.

Energy Efficiency and Moisture Control

The pre-dehydration function minimizes heat loss from instant vaporization, leading to significant energy savings. By reducing the wet embryo’s moisture content to ≤50%, it helps prevent carbonization blockage and more than doubles the mold cleaning cycle.

Optimized Structure and Heat Management

Bottom mold material retrieval resolves wet embryo transfer issues while reducing energy loss from unnecessary hot pressing. The compact inline structure (approx. 10,000 × 1,750 mm) uses less than half the space of robotic systems, improving space utilization.

Precision Engineering and Ease of Use

An internal high-reliability transfer system supports high-precision products with demanding sealing, height, and angle requirements. A multi-point force design ensures even heating and pressure for better hot pressing results, while a user-friendly layout (≤1400 mm height) ensures easy maintenance without surrounding obstructions.

Our Clients from the World

Asia :China,South Korea,Vietnam,Thailand,Philippines,Malaysia,Indonesia,Singapore,India,Iran,Saudi Arabia,Yemen,Kazakhstan,Uzbekistan,Turkmenistan,Iraq,Oman,Lebanon,Syria,Azerbaijan

Europe:Britain,France,Denmark,Poland,Czech Republic,Hungary,Ukraine,Russia,Turkey,Albania,Serbia,Slovakia,Belarus,Lithuania,Estonia,Austria

South America: Colombia,Ecuador,Brazil,Bolivia,Chile,Argentina,Uruguay

Central America:Honduras

North America:United States,Mexico

Oceania:Australia,New Zealand

Africal: Egypt, Libya, Algeria, Morocco, Tunisia, Mali, Sudan, Nigeria, Cameroon, Uganda, Madagascar